The experts at Mockingbird Bell Technical Services provide solutions to a wide range of vacuum technology and contamination control needs. They have decades of experience in system design, operation, maintenance and troubleshooting. In today’s fast paced, lean manufacturing environment, it is difficult to maintain expertise in every technology used in your work. Let MTBS staff help you with your vacuum equipment and process needs while you focus on your core business competencies.

Navac Vacuum Pumps

Learn More About Navac Vacuum Pumps

Tracer Gas Leak Detection

Learn More About Our Tracer Gas Leak Detection

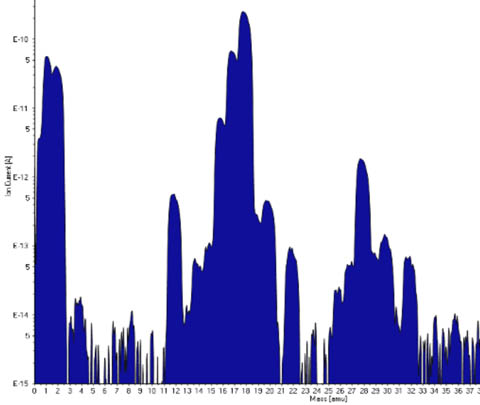

Residual Gas Analysis and Mass Spectroscopy

Learn More About Residual Gas Analysis and Mass Spectroscopy

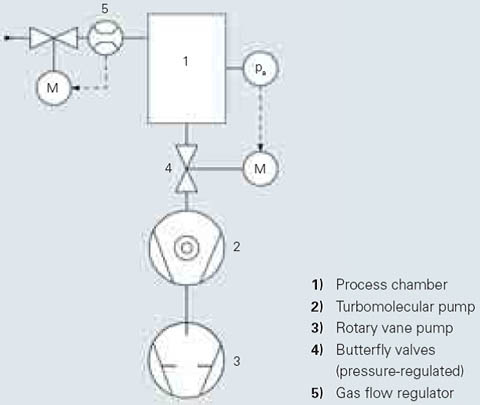

Vacuum System Configuration and Trouble Shooting

Learn More About Vacuum System Configuration and Trouble Shooting

Cleanrooms & Contamination Control

Learn More About Cleanrooms and Contamination Control

Process and Equipment Monitoring & Control

Learn More About Process and Equipment Monitoring & Control